Manufacturing

Power and Controls manufactures a wide range of products. We specialise in all types of LT Panels and have successfully completed supply in many private as well as government organisations. Some of our products are listed below:

Power and Controls manufactures a wide range of products. We specialise in all types of LT Panels and have successfully completed supply in many private as well as government organisations. Some of our products are listed below:

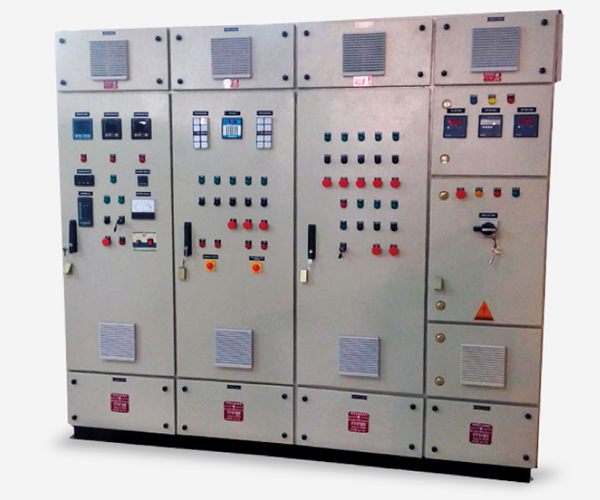

Basic function of PCC Panels is to control power supply to various units and equipment in the industry as per the load requirement. It is designed based on the needs of the client depending upon the incoming and outgoing ACB/MCCB/SFU/MCB.

Normally, PCC Panels comprise of either Breaker Panels only or Breaker and MCC Panels coupled together. They are installed near power source and hence fault level is very high. Busbar system inside PCC Panels are designed to safety against the fault level, change in climatic conditions (temperature), short circuit, over voltage, etc. to ensure safety to all machineries and equipment.

We offer PCC Panels with Current carrying capacity of upto 6300 Amps integrated with necessary protection to meet all safety standard as required in various industries.

MCC Panels are used in majority of industrial applications.LT Power is distributed using these panels. They are effectively used to control motors or submersible pumps to provide sufficient protection from overloads and short circuits. These are high on performance, require low maintenance and can withstand extreme temperature variations.

We offer MCC Panels as per costumer requirement using ACB/MCCB/SFU/MCB, DOL, Star Delta Starters or ATS for Automatic/Manual means of starting & stopping the motor. Our MCC can be operated via Local/Remote/DCS.

Modern power networks consist of a wide variety of electrical and power electronics loads, in case of which, the power factor also varies as a function of the load requirements depending upon the type of machineries, cooling plants and other devices installed. APFC Panels are therefore used in commercial buildings and industries due to their capacity to automatically control load power factor by sensing various parameters like current, power and KVAR without any manual intervention. In addition, the occurrence of leading power factor will be thus prevented, minimising the loss and wastage of energy and heavy penalties by various electricity boards.

Our APFC panels are manufactured using APP/MPP Heavy Duty capacitors banks as per characteristics of electric loads.

Synchronizing Panel works between two or more different power sources like DG sets to manage power supply. Synchronization helps in making different DG sets behave as a single virtual unit and eliminates subdivision of total load. It helps in transferring load from one unit to another as during service period, so that the unit requiring service can be easily shut off. In this way the critical load need not be interrupted and thus there is no production loss. They can be controlled both manually and automatically based on the client requirements. As special features we provide Synchronising Panel with AMF and PLC so that it can be controlled and monitor from control room.

The VFD Panels (Variable Frequency drive panels), also known as VFD Control Panels or AC Drive Electrical Control Panels, are designed to control the speed of electric motor and feed pump. They are widely used in drilling, pumping and other large machine applications like rolling Mills, tube mills, paper mills, cable industry and CTL Lines.Basic use of VFD Panels include: power switching and protection, adjustable speed of the transmitted command signals to the motor, it can display the panel’s operational status visually and reduce the impact of external environment to the electrical components. As a special feature we can provide DOL/SD Starter so that in case of VFD breakdown one can run the motor without any trouble.

Soft starter panels are fully equipped with all necessary switch-gears like MCCB, Bypass Contactor and Soft Starters. They protect the mechanical power-transmitting elements of the machines during start-up and ramp down. They guard the network against high inrush peaks through reduced power input efficiently and provide safety against Over Load, Over Current, Under &Over Voltage etc.

Soft Starter Panels have a graphic display and a logical keypad which enables advanced setup and viewing of operational status.

The feeder pillar panels are used to terminate and distribute the control circuits. They provide local isolation to the electrical distribution equipment, protecting both the cabling and the transformer from faults. These are used in almost all the industries, townships and housing as they allow simple and local maintenance to our equipment, reducing site downtime and reducing overall maintenance costs.

A fire alarm control panel (FACP), fire alarm control unit (FACU), or simply fire alarm panel is the controlling component of a fire alarm system. The panel receives information from devices designed to detect and report fires, monitors their operational integrity and provides for automatic control of equipment, and transmission of information necessary to prepare the facility for fire based on a predetermined sequence. The panel may also supply electrical energy to operate any associated initiating device, notification appliance, control, transmitter, or relay.

Main components of a fire alarm panel include interface, battery, SLC Loops, Notification appliance circuits (NACs), Relays, Phone Jacks, Power conditioner, cabinet and main circuit board. Large buildings or campuses have multiple panels installed that are linked with Local Area Network or LAN. All integrated detection systems can be addressed and monitored from a single panel or monitoring station.

Also referred to as automatic transfer switch (ATS) panels – AMF Panels make the power switch to emergency standby generators in the event of a significant loss of mains power or total blackout. Without AMF panels, generators need to be operated manually and that can lead to loss in data, potential damage to electrical equipment and huge amounts of disruption.

Once the generator is ready to accept the load, the motorised switches or contactors in the AMF panel will switch the building load from mains supply to the generator. When the mains is restored, the opposite will happen. The AMF panel will put the building load back on to the mains supply and then stop the generator (once it has performed its cool down process).

These boxes cater the needs of electrical power distribution in various Utilities/infra projects. Apart from Distribution boxes we also deal with Junction Boxes, Energy Meters, Electrical Kiosks that can be tailor made based on customer specific requirements and designs.

For any kind of requirements please contact us at

info@powerandcontrols.co.in for prompt response and special rate.

| 55, Ezra Street, Basement A.C. Market, Suit No. 20, Kolkata-700 001 |

|

| SK Industrial Plaza, Kalagachia Sakaripota Main Road, Thakurpukur, Behala, Kolkata 700063 |

|

| 033 2235 7326 / 033 2235 7327 | |

| info@powerandcontrols.co.in |

Copyright © Power & Controls 2025. All rights reserved.